Brand: Geissele Automatics

Brand: Geissele Automatics

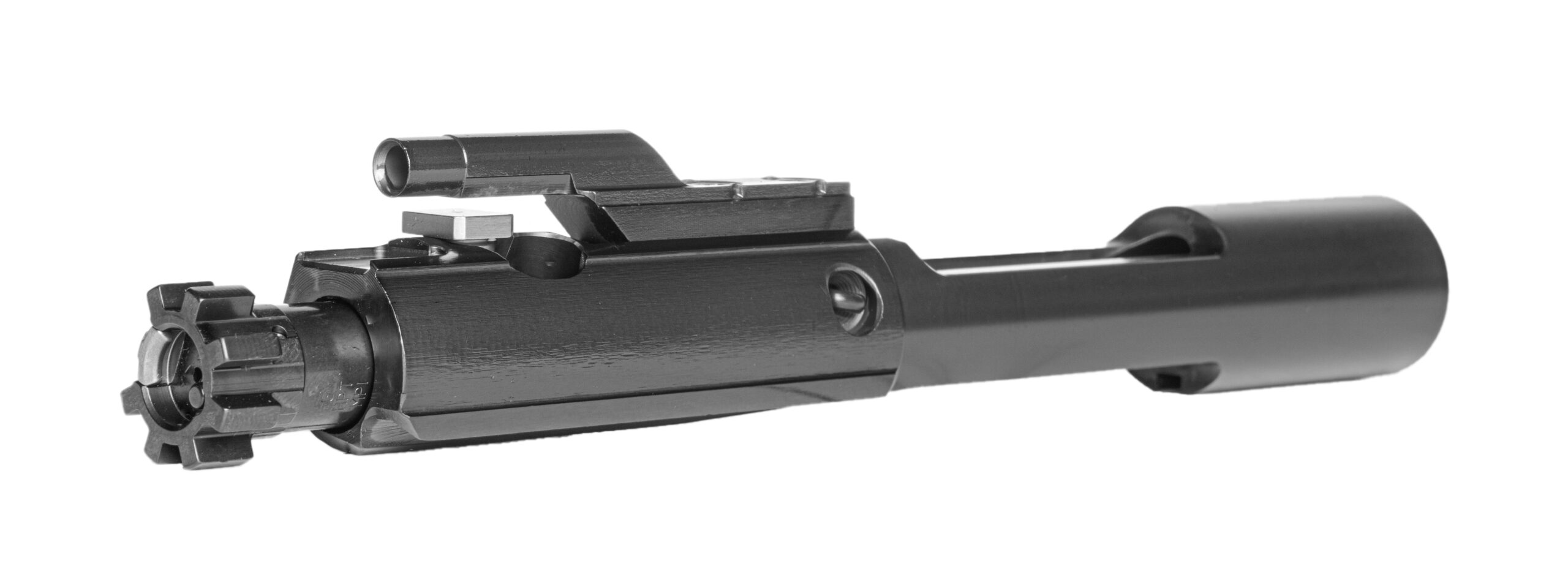

Geissele .223/5.56 Reliability Enhanced Bolt Carrier Group - 05-1014

$385.00

November Savings Sale: use code BFMONTH12OFF for an additional 12% off this item.

If the price drops within 30 days of your purchase, we’ll credit the difference.

If the price drops within 30 days of your purchase, we’ll credit the difference.

Out of stock

Join the waitlist to be emailed when this product becomes available

SKU: 4745 Categories: AR-15 BCGs, Bolts, Carriers & BCGs (Bolt Carrier Groups) DescriptionThe Reliability Enhanced Bolt Carrier Group (REBCG) is a 5.56mm full-mass, full-auto rated M16/M4 bolt carrier group manufactured in Geissele’s state-of-the-art manufacturing facility in North Wales, PA. The carrier is machined from mil-spec 8620 steel, and features a properly torqued and staked, chrome lined, gas key. The cam pin is machined from an advanced medical steel typically used to produce medical instrumentation known as H13, it is then coated with Nanoweapon (Chrome-Nitride) for maximum corrosion and wear resistance. The extended upper rails on the carrier also provide much greater stability and dramatically increase feeding reliability. The Carrier is coated with Nanoweapon for maxium corrosion and wear resistance.

The Geissele Stressproof Bolt is made from Carpenter 158, however this is not your typical material spec’d by the US Government. Since Geissele wanted to take it to the next level, our engineers worked directly with the Carpenter Steel metallurgists in Reading PA, to produce a special heat of material known as Carpenter 158+. This material is cleaner with less impurities, ultimately making it stronger and more consistent. We did not stop there, we decided to forge the bolt. Using the same process used to produce upper and lower receivers, a forged bolt manipulates the grain structure of the metal and yields a bolt capable of 5 times the life of a mil-spec bolt. Each bolt is then rigorously inspected, high pressure tested, mag particle inspected and coated with Nanoweapon for maximum corrosion and wear resistance.

Nanoweapon is a family of coatings similar to DSL (Durable Solid Lubricant) that was developed by Picatinny Arsenal (US ARMY ARDEC), and is only available exclusively from Geissele Automatics. Our engineers worked for over 3 years with the research and development company that worked with Picatinny to develop the coating in order to fine tune it into what it is today, making it the pinnacle of coatings for firearm components. No other coating on the market can provide the same level of corrosion, wear, and abrasion resistance as Nanoweapon. The coating is applied at low temperatures so it does not affect the metallurgy of the part, and has a surface hardness equivalent of 82HRC. At that hardness, it is harder than sand, easily rejecting carbon and making cleaning a breeze, on top of allowing the firearm to operate normally with less lubrication.

Additional information| Weight | 11.408 oz |

|---|---|

| Bolt Material | Carpenter 158 |

| Cartridge Compatibility | .223/5.56 NATO/.300 BLK |

| Finish | Nanoweapon Chrome Nitride |

| Carrier Profile | M16 |

| High Pressure Tested | HP Tested |

| Magnetic Particle Inspected | Magnetic Partical Inspected |

| Platform | AR-15 |

| Bolt Finish | Nanoweapon Chrome Nitride |

| MPN | 05-1014 |

| UPC | 05-490 |

Compliance

NFA (National Firearms Act) compliance is crucial for legal ownership and transfer of regulated firearms and accessories like short-barreled rifles, suppressors, and certain types of ammunition, ensuring adherence to federal regulations to avoid legal penalties and ensure responsible firearm ownership.

ReviewsPlease select an FFL from the table below, if you do not see your desired FFL, click "Set Later" and you will be able to enter your FFL's information after checkout.

| Name | City | State | ZIP | Phone | |

|---|---|---|---|---|---|

| Loading FFL contacts, please wait... |

Please select an FFL from the list.

Please select an FFL from the list.